Operational flexibility and resiliency, as we have learned, is a must in the face of a massive, unexpected global event, or other disruption such as weather, fluctuating demand, geopolitical instability, or supply constraints. Organizations across industries are moving to a shared operations & expertise approach by working more closely with industry ecosystem partners in and even outside their industry.

In the early days of the pandemic, for example, General Motors worked with Meditech to develop and produce ventilators; more recently, Johnson & Johnson partnered with industry competitor Merck to source additional production capacity and capability, as well as quality and compliance expertise. Manufacturers and retailers, according to the 2020 IDC Supply Chain survey, currently state one of their top focus areas to be development of and access to multi-enterprise networks – for on-demand procurement, trade, commerce, and service capability. Organizations in every industry continue to leverage open innovation practices to tap into expert networks for ideation and problem solving.

But will the close operational and innovation partnerships that have emerged and accelerated over the past year during the pandemic continue, after we proceed to the “next normal”? We think so.

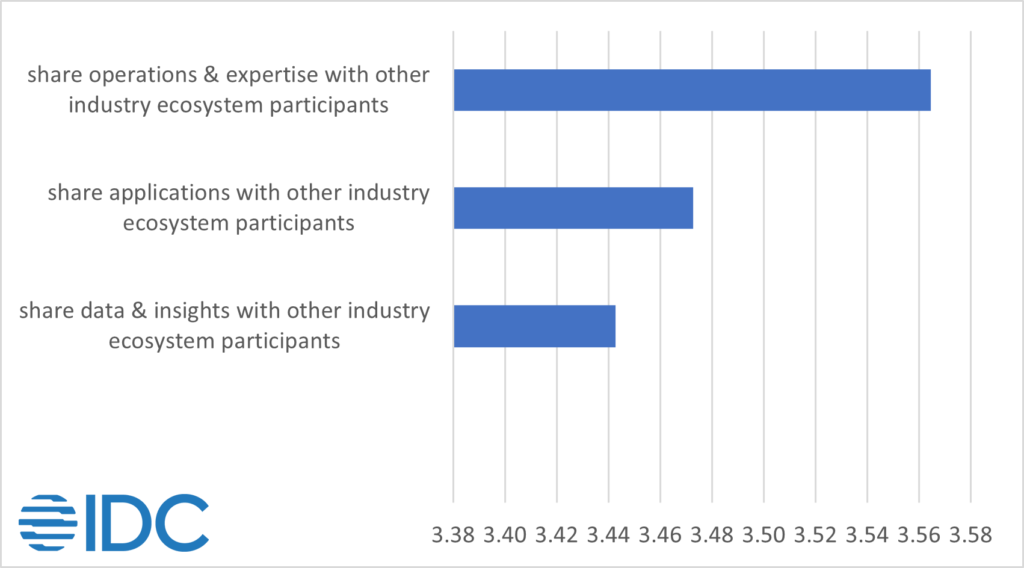

According to the IDC Future Enterprise Resiliency Survey, Feb 2021, CEOs are prioritizing investments to support digital transformation, and industry ecosystems. The more recent IDC Future of Industry Ecosystem Global Survey, May 2021, confirms the importance of shared operations and expertise as part of an industry ecosystem strategy (figure 1).

Figure 1: Shared Operations a Leading Future of Industry Ecosystem Initiative

In comparison with prior to the COVID-19 pandemic, how likely is your organization to do the following?

Source: Future of Industry Ecosystems Global Survey, May 2021

Shared Operations & Expertise is Real Today

Organizations working together to create value, meet customer, citizen, or patient needs, and realize their respective industry ecosystem mission is already happening today in every industry. While in some cases the motivation for sharing operations or expertise may have been situational, ecosystem partners quickly realize the mutual benefit, and continue this approach as part of their regular collaboration and interaction with other participants as an augmentation to their home-grown capacity and capability.

Shared Operations and Expertise is critical for a company to be resilient and flexibly scale capacity and innovation to meet market needs, solve problems and provide customer/citizen support and resources, as required. In manufacturing industries, manufacturing as a service (MaaS) has evolved over the years from a network of machine shops to full-service contract manufacturers to manufacturing marketplaces. IDC defines manufacturing as a service as distributed, shared use of manufacturing infrastructure, R&D, and engineering capabilities to support the design, development, production, delivery, and operation of products and related services.

This approach can be used to support the entire manufacturing process chain or specific domains, initiatives, and projects such as design rendering and prototyping, computer numerical control (CNC) machining, or additive manufacturing. The consumption and capabilities of manufacturing as a service will continue to expand because of the growth of 3rd Platform, digital technologies. Other industries are also moving to a shared operations and expertise approach. In healthcare during the pandemic, hospitals and pharmaceutical companies have organized digital “ventilator challenges” and set up open innovation websites for pandemic vaccine research. With the move to digital commerce and contactless delivery, retailers have ramped up the usage of shared cloud infrastructure to support the digital traffic and communication that needs to occur.

Why is Shared Operations & Expertise Needed?

An external source of operational capacity and knowledge is critically important for organizations in every industry to be flexible and resilient. In support of this, there is a focus on not only expanding the number and types of different partners, but also enhancing how existing companies work together. From a static, occasional collaboration to a dynamic, iterative approach where the partner, supplier, or service provider becomes an extension of your team. This approach can provide the support to scale operations up and down as needed, whether for innovation, production, supply chain, IT support, customer service, or service/customer experience delivery. Shared operations and expertise also provides the all-important “bench” of talent and skills that you can access on demand and as needed.

Shared operations and expertise is clearly a focus initiative for organizations today and in the future as they evolve their industry ecosystem strategy. This is, however, only one aspect of a Future of Industry Ecosystem approach: the most successful organizations will complement sharing of operations and expertise with the optimal balance of shared and co-developed data, insights, and applications.

For each industry and each organization, this balance will be unique. What has become abundantly clear over the past year is that it is very difficult for an organization to respond to massive disruption on their own, often due to skills, knowledge, and operational capacity and capability shortage. Industry ecosystems play an important role in filling these gaps, and increasingly leading organizations are realizing this.

For more information on the shared operations and expertise approach, the three categories of use cases for this approach and its importance to the Future of Industry Ecosystems framework, read IDC’s new complimentary eBook, “Future of Industry Ecosystems: Shared Operations & Expertise”. Click the button below to download.