Register for the Environmental, Health, and Safety (EH&S) Market Update webinar on August 18th at 11 AM/EDT to take a deeper dive into this topic with Reid Paquin and learn how companies are adapting their operations with digital capabilities and resilient decision-making.

The Pressures from the Global Pandemic

While the entire world tries to manage the uncertainty of COVID-19 and its impact, industrial organizations like those in manufacturing, energy, or mining, have felt the pressure more than most. In fact, IDC’s Worldwide ICT Spending Guide has shown that roughly $1.3 trillion has been lost because of the global pandemic, with these industries overwhelmingly as the most impacted.

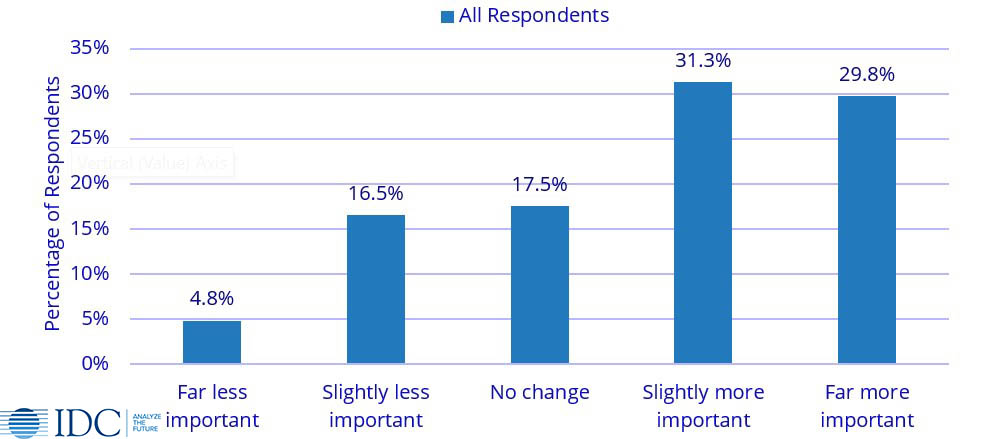

While many industries have shifted their company to a work from home model, the reality is that industrial facilities need to stay operational to produce necessary goods for the global community; and for this to happen people must continue to work on the plant floor. Coincidentally, IDC recently launched a new research study on the topic of sustainability and EH&S across manufacturing, oil & gas, utilities, and mining. While EH&S has been a consistent part of operations for decades, the unique challenges presented by COVID-19 has caused a noticeable shift on the importance of these programs (Figure 1).

Figure 1: Impact of COVID-19 on the Importance of Industrial EH&S

Reducing the Spread

There is no denying the fact that the manufacturing industry will see short-term and long-term changes as the dust settles around COVID‐19. The immediate concern for most manufacturers is to keep their employees safe and healthy as operations continue to ramp up across the globe. There are a variety of actions that manufacturers are taking to create a safer working environment for their essential employees.

This includes the creation of temperature monitoring checkpoints to ensure employees arriving to work do not have a fever (a potential pre-cursor for the virus), as well as the introduction of personal protective equipment (PPE) requirement to reduce the likelihood of employees contacting or spreading the virus while working. The most advanced manufacturers are turning to video based systems to monitor the workforce and ensure that social distancing is being followed and if a positive test does occur contact tracing can be utilized to identify and isolate employees that could be at risk.

One of the biggest challenges that companies have faced as a result of COVID-19, especially at the onset, is how quickly change occurred. Governments were adjusting as more information became available, resulting in regulatory and compliance mandates changing shortly after. Occupational Safety and Health Administration (OSHA) for example released guidance on protecting manufacturing workers.

Staying on top of current and future regulations was always a top concern for EH&S programs, however the pace of change has never been at what it is today. The impact of non-compliance can include penalties, fines, damage to brand image, erosion of shareholder value, plant shutdowns, and even, in the worst cases, fatalities. Unfortunately, the age-old mindset concerning industrial EH&S typically waited for an adverse event to occur for investments to be made.

Shifts in Priority

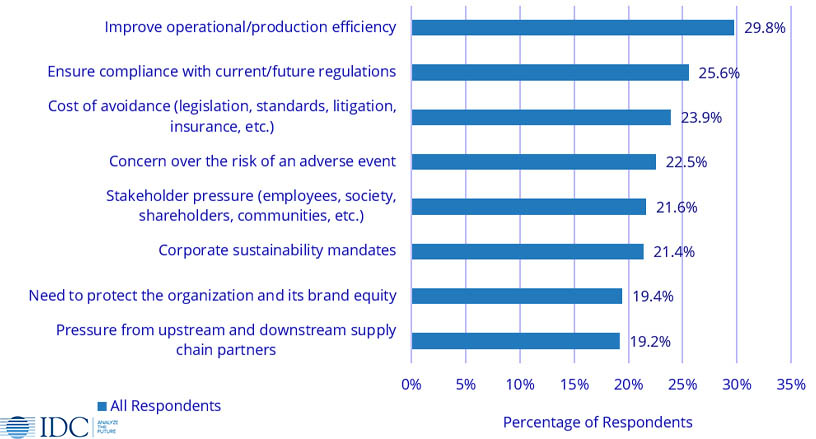

While EH&S programs have historically been relied upon to combat rising insurance costs, reduce incidents, and ensure regulatory compliance, if that is all that is being considered then a company is not maximizing their potential. More and more organizations are coming to the realization that EH&S can also be used to promote operational excellence, in fact it is now the top pressure cited (Figure 2).

Figure 2: Top Pressures Driving Focus on Environment, Health, and Safety (EH&S)

In the wake of COVID-19, industrial organizations are under heightened pressure to contribute value to the organization’s bottom line by cutting costs and improving productivity wherever possible. Unfortunately, in the past, it was far too easy for companies to become too focused on efficiency and as a result, sacrificed employee safety. This is no longer an option; government bodies are now paying close attention to the health and safety of the populace; non-compliance can result in a complete shutdown of the business.

Leaders in the industry are looking at new ways to have the best of both worlds – a safe working environment for employees and efficient operations. In fact, from the survey, on average 5% of a company’s unscheduled asset downtime can be attributed directly to a safety or environmental incident. Even if that number is just cut in half, the resulting savings could be in the millions for most industrial organizations.

A key attribute of Best-in-Class companies that was uncovered in the Industrial EH&S survey was the close collaboration that occurs between continuous improvement teams and the EH&S group. In addition, many industrial organizations are applying the same lean principals they have relied upon for decades to environment, health, and safety to cut out waste. Also, shifting away from lagging indicators (like incident rates and worker compensation costs) alone and incorporating leading indicators (like safety culture assessments and time to respond to audits/hazard reports) to predict EH&S issues before they occur is a growing method for success.

These are just a few of the steps that companies can take to break the thinking that EH&S programs reduce operational productivity. There are many more business capabilities and technology investments explored in the full survey that can allow EH&S to change from a cost avoidance measure to a profit center driving tangible operational benefits.

The Importance of EH&S

The industrial environment is changing faster than ever before. Digital technologies like cloud, mobility, big data/analytics, and AI are drivers for industry transformation, but EH&S is often overlooked for these investments. This needs to change as IDC research has shown that the combination of digital technology and a high focus on sustainability/EH&S leads to increased revenue and profit.

While COVID-19 has put a spotlight on worker health & safety, if approached properly, the investments being made today lead to sustained success. While the global pandemic has put a spotlight on worker health & safety, companies making the proper investments today will allow them long-term sustained success – ensuring worker safety from all hazards while improving productivity.

For a more in-depth view on the state of industrial EH&S and how successful organizations are balancing the short and long term, please attend my upcoming Environmental, Health, and Safety (EH&S) Market Update webinar on August 18th at 11 AM/EDT.